Commercial & Industrial Steam Cleaners | Pure Steam Cleaners.uk

- Order Before 1pm For Free Next Working Day Machine Delivery!

- UK’s Only Self Descaling Steam Cleaners

- Order Before 1pm For Free Next Working Day Machine Delivery!

Industrial Steam Cleaners for Equipment Maintenance: An Overview

In the industrial sector, equipment maintenance is a critical aspect that ensures smooth operations and maximises the lifespan of machinery. Over time, industrial equipment can accumulate dirt, grime, and other contaminants, which can affect its performance and efficiency. To tackle these challenges, industrial steam cleaners have emerged as a reliable and efficient solution for equipment maintenance. In this article, we will delve into the world of Industrial steam cleaners for equipment maintenance and explore their applications, benefits, and considerations for effective use.

Understanding Industrial Steam Cleaners

Industrial steam cleaners are powerful machines designed to clean and sanitise various surfaces using high-pressure steam. These cleaners utilise the unique properties of steam to dissolve tough dirt, grease, and residues, making them ideal for heavy-duty applications. The high-temperature steam produced by these cleaners not only cleans the surface but also eliminates harmful bacteria, germs, and allergens, providing a hygienic environment.

The Science Behind Steam Cleaning

Steam cleaning involves the transformation of water into steam by heating it to a high temperature. When the steam comes into contact with a surface, it releases its latent heat energy, which effectively dislodges dirt particles and contaminants. The steam’s high temperature softens and breaks down grime, making it easier to remove, while the moisture content helps to lift and flush away the loosened dirt. This combination of heat and moisture makes steam cleaning a highly efficient and eco-friendly method.

Applications of Industrial Steam Cleaners

Industrial steam cleaners find widespread use in a variety of applications, including equipment maintenance. Let’s explore some of the key areas where these cleaners prove to be indispensable.

1. Machinery and Equipment Cleaning

Industrial equipment, such as heavy machinery, production lines, and processing units, often requires thorough cleaning to maintain optimal performance. Steam cleaners can effectively remove oil, grease, dust, and other contaminants that accumulate on machinery surfaces. The high-pressure steam reaches into tight spaces and crevices, ensuring a comprehensive and deep cleaning, thus prolonging the equipment’s lifespan and reducing the risk of breakdowns.

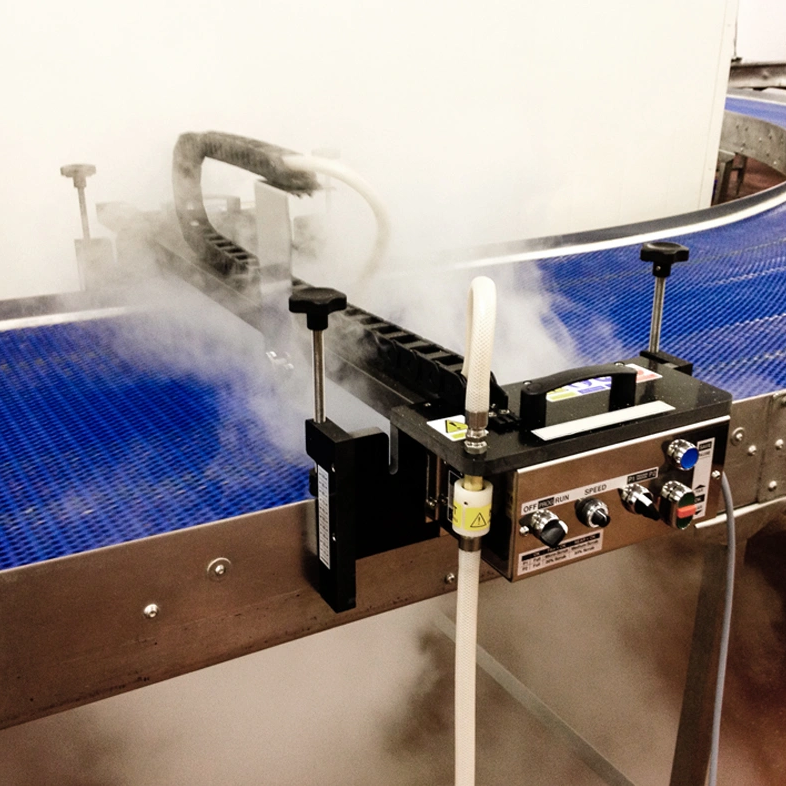

2. Conveyor Belt Maintenance

Conveyor belts play a crucial role in many industries, facilitating the movement of goods and materials. However, due to constant use, these belts can accumulate debris and become contaminated. Steam cleaners offer a convenient and efficient method to clean conveyor belts, removing dirt, oil, and residue buildup. The high-temperature steam effectively sanitises the belts, eliminating bacteria and ensuring hygienic operations.

3. Tank and Vessel Cleaning

Industrial tanks and vessels, such as storage tanks and silos, require regular cleaning to prevent the buildup of sediments, residue, and contaminants. Steam cleaners provide an effective solution for tank and vessel maintenance, as the high-pressure steam can penetrate and dislodge stubborn deposits, ensuring thorough cleaning. The use of steam also eliminates the need for harsh chemicals, making it a safer and environmentally friendly option.

4. HVAC System Cleaning

Heating, ventilation, and air conditioning (HVAC) systems are vital for maintaining a comfortable and healthy indoor environment. However, these systems can accumulate dust, mould, and other allergens over time, leading to reduced efficiency and potential health hazards. Industrial steam cleaners can effectively clean HVAC components, including air ducts, vents, and coils, removing contaminants and improving the system’s performance.

5. Facility Maintenance

In addition to specific equipment cleaning, industrial steam cleaners are also beneficial for general facility maintenance. They can be used to clean floors, walls, windows, and other surfaces, eliminating dirt, stains, and germs. The versatility of steam cleaners makes them a valuable asset for maintaining cleanliness and hygiene in industrial settings.

Benefits of Using Industrial Steam Cleaners

Industrial steam cleaners offer numerous benefits for equipment maintenance. Let’s explore some of the key advantages they provide:

1. Efficiency and Time Savings

Compared to traditional cleaning methods, steam cleaning is much faster and more efficient. The high-pressure steam and targeted cleaning attachments allow for thorough and precise cleaning, reducing the time required for maintenance tasks. Additionally, steam cleaners can reach difficult-to-access areas, ensuring comprehensive cleaning without disassembling the equipment.

2. Environmentally Friendly

Steam cleaning is an eco-friendly alternative to chemical-based cleaning methods. Since steam cleaners only use water and heat, they eliminate the need for harsh chemicals that can be harmful to the environment. This makes steam cleaning a sustainable option for equipment maintenance while ensuring the health and safety of workers.

3. Versatility

Industrial steam cleaners are versatile tools that can be used for a wide range of cleaning tasks. From delicate surfaces to heavy machinery, these cleaners can adapt to various cleaning requirements. With interchangeable cleaning attachments, steam cleaners offer flexibility and allow for customised cleaning approaches.

4. Enhanced Equipment Longevity

Regular maintenance and cleaning contribute to the longevity of industrial equipment. By using steam cleaners for equipment maintenance, you can effectively remove dirt, grease, and contaminants that can cause wear and tear. This helps to extend the lifespan of machinery, reducing the need for frequent repairs or replacements.

5. Improved Hygiene and Safety

![]()

Maintaining a clean and hygienic industrial environment is crucial for ensuring the safety of workers and preventing contamination. Industrial steam cleaners provide deep cleaning and sanitation, eliminating bacteria, germs, and allergens from equipment surfaces. This promotes a healthier workplace and reduces the risk of product contamination or employee illnesses.

Considerations for Effective Equipment Maintenance with Steam Cleaners

While industrial steam cleaners offer numerous benefits, there are certain factors to consider to ensure effective equipment maintenance. Paying attention to these considerations will help you make the most of your steam cleaning efforts:

1. Equipment Compatibility

Before using a steam cleaner on industrial equipment, it’s essential to ensure compatibility. Some delicate or sensitive equipment may not withstand the high temperatures or moisture produced by steam cleaners. Refer to the equipment manufacturer’s guidelines or consult with cleaning professionals to determine the suitability of steam cleaning for specific machinery.

2. Operator Training

Operating industrial steam cleaners requires proper training to ensure safe and effective cleaning. Train your staff on how to handle steam cleaners, including proper handling of attachments, adjusting steam pressure, and maintaining safety protocols. This will minimise the risk of accidents and maximise the efficiency of cleaning operations.

3. Maintenance Schedule

Establishing a regular maintenance schedule is crucial for the optimal performance of industrial equipment. Integrate steam cleaning into your maintenance routine, ensuring that equipment is cleaned at appropriate intervals. By implementing a proactive maintenance approach, you can prevent major breakdowns and prolong the lifespan of machinery.

4. Post-Cleaning Drying

After steam cleaning equipment, it is important to allow sufficient drying time before resuming operations. Excess moisture can lead to corrosion or electrical hazards, so ensure that equipment is thoroughly dried. Depending on the nature of the machinery, you may need to employ additional drying techniques or use specialised equipment to expedite the drying process.

5. Maintenance Documentation

Maintaining comprehensive documentation of equipment maintenance activities is essential for tracking cleaning schedules, monitoring performance, and ensuring compliance with regulations. Implement a system to record steam cleaning activities, including dates, equipment cleaned, and any relevant observations or findings. This documentation will serve as a valuable reference for future maintenance activities.